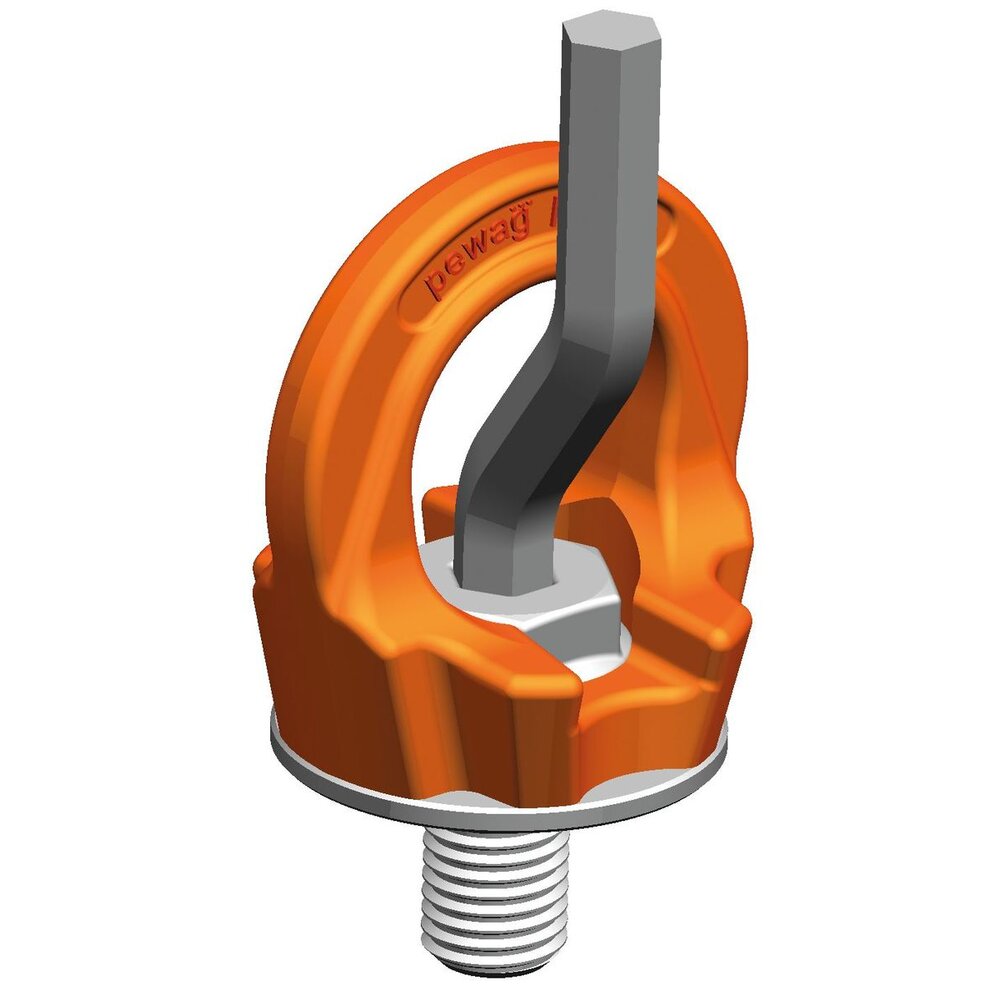

Pewag winner profilift gamma supreme – tighten by hand, then align in the load direction, a lifting point that has been developed and produced with the new standards in mind. The patented system has proven itself from the beginning.

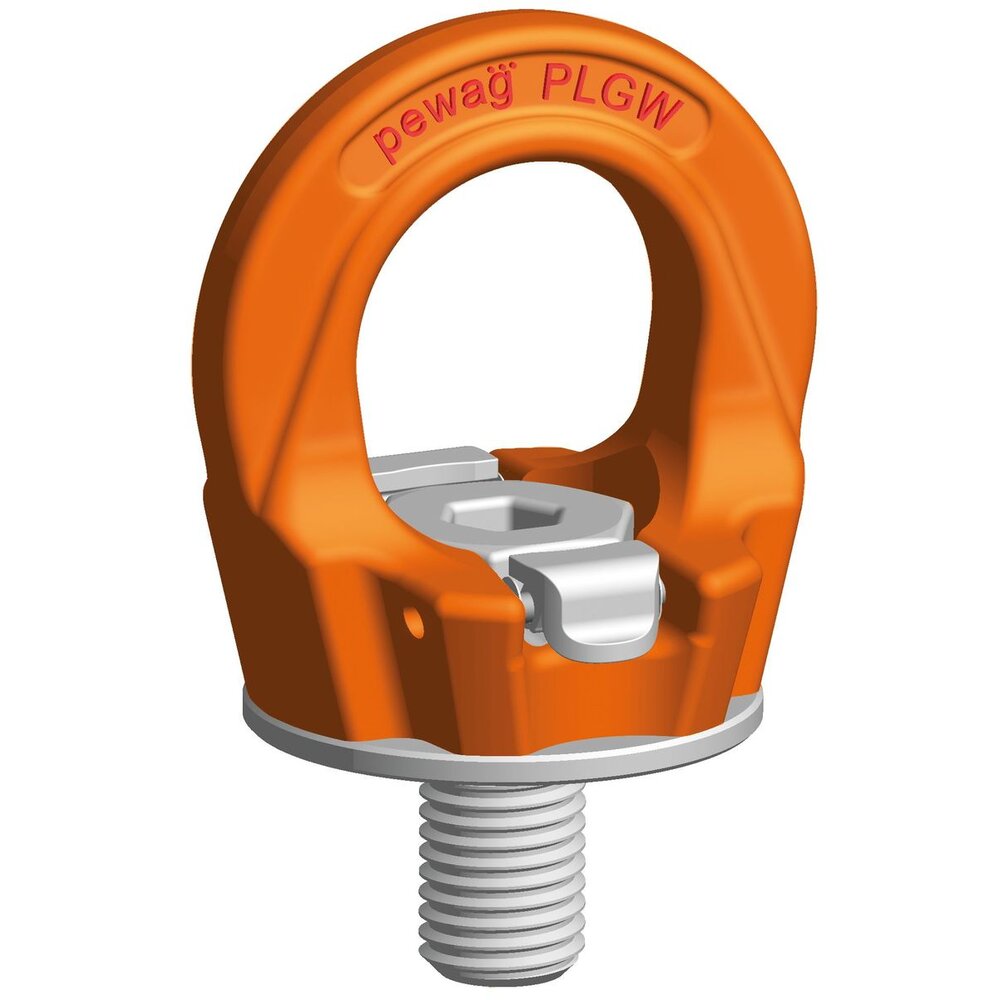

It is 360° rotatable, contains a patented and interchangeable special screw, which is 100% crack-tested as well as covered with a chrome VI-free finish-protection against corrosion and marked with WLL and thread size.

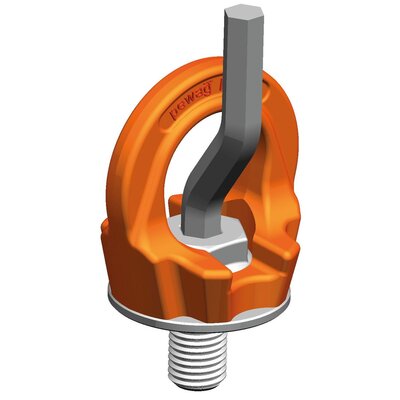

Tool-free assembly and disassembly.

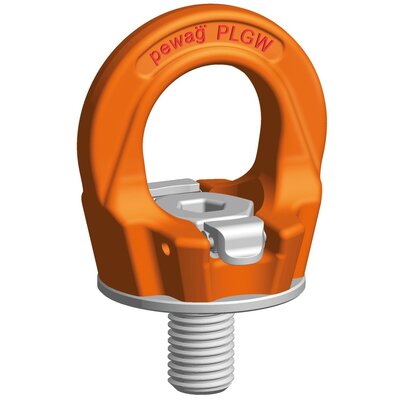

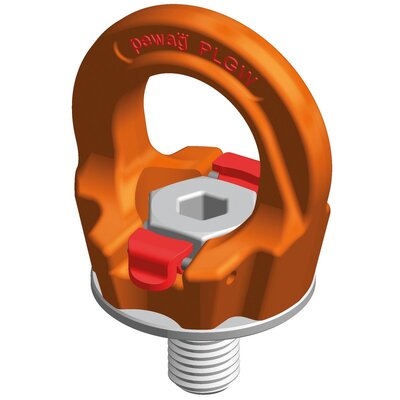

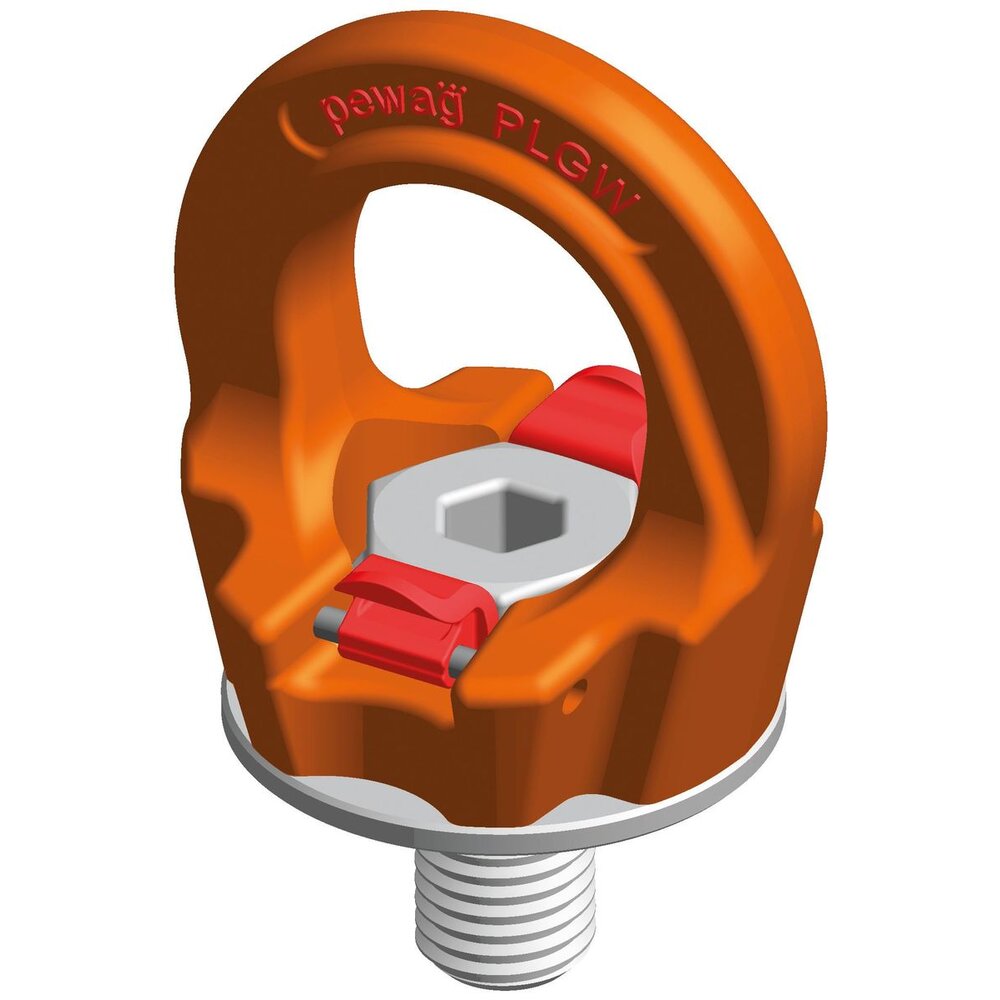

The latch in pos.1 does not have any contact with the screw (picture 1).

- The latch is kept in position with a patented spring

- Eye bolt is rotatable

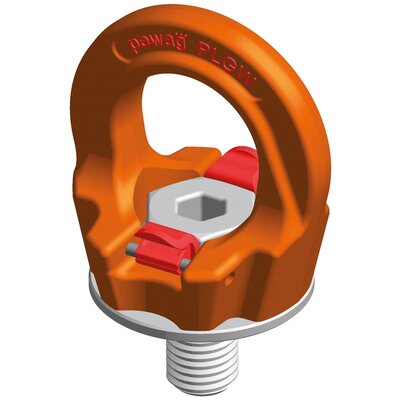

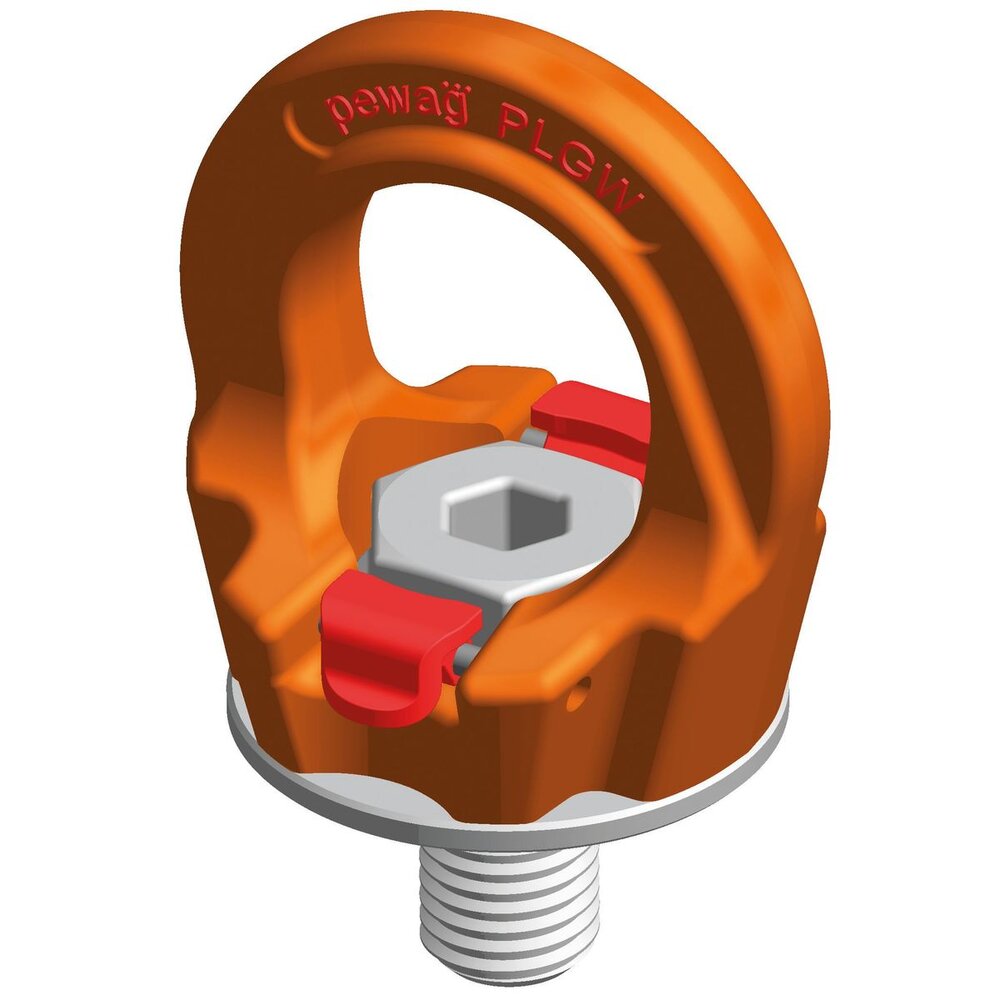

The latch in pos. 2 has contact with the screw (picture 2).

- The latch is kept in position with a patented spring

- Eye bolt is not rotatable i.e. the fastening torque is transmitted to the screw and thus the eye bolt can be (re)assembled.

A considerably simplified alternative is the pewag PLGW pewag winner profilift gamma basic. With the same benefits as the pewag PLGW supreme in terms of measurement, carrying capacity and application, the pewag PLGW basic differs solely in the assembly: mounting and removing requires the use of a hexagon Allen wrench.

Permissible usage

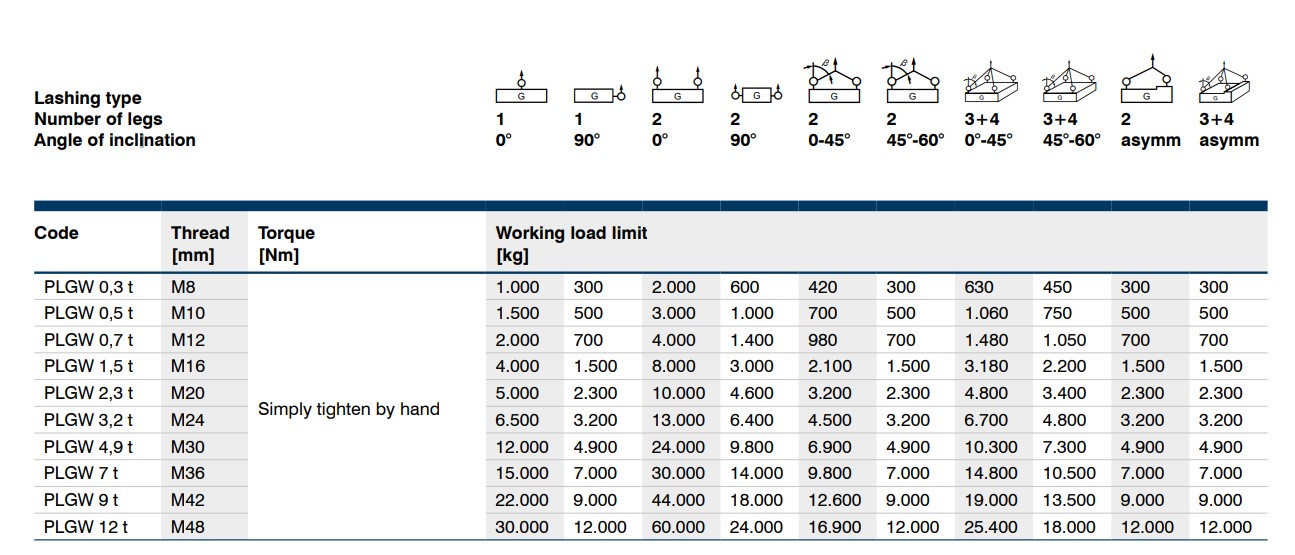

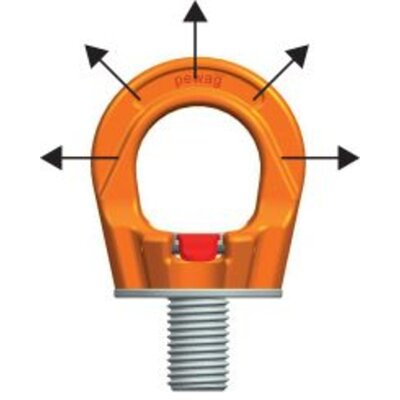

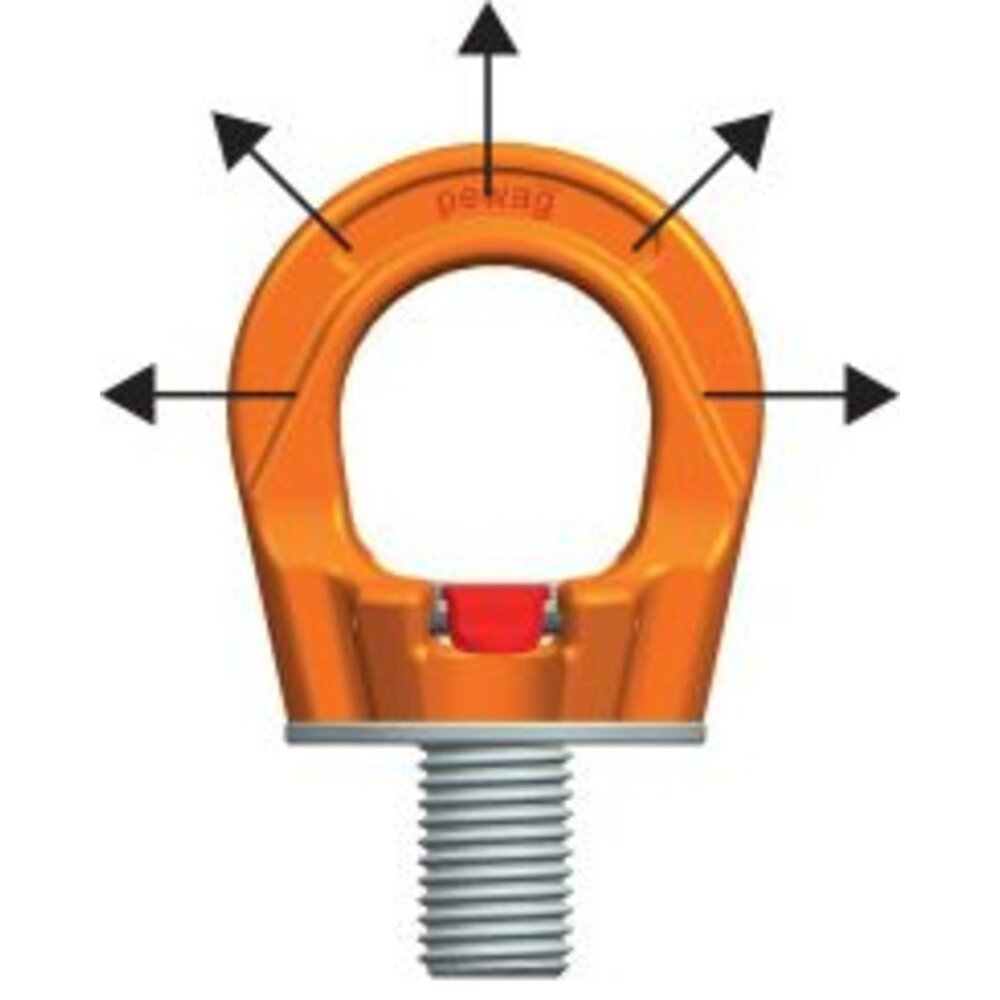

Load capacity acc. to the inspection certificate table of WLL in the shown directions of pull (see picture 3).

- Adjust the lifting point in the permitted load direction before loading

- Loadable with a 4-fold safety under break in all directions

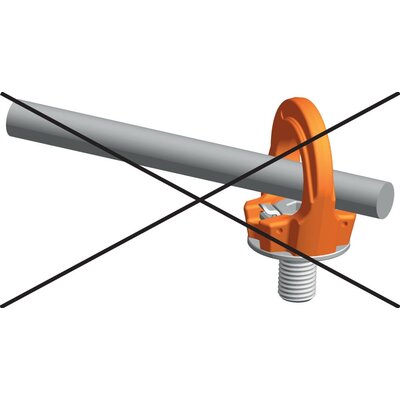

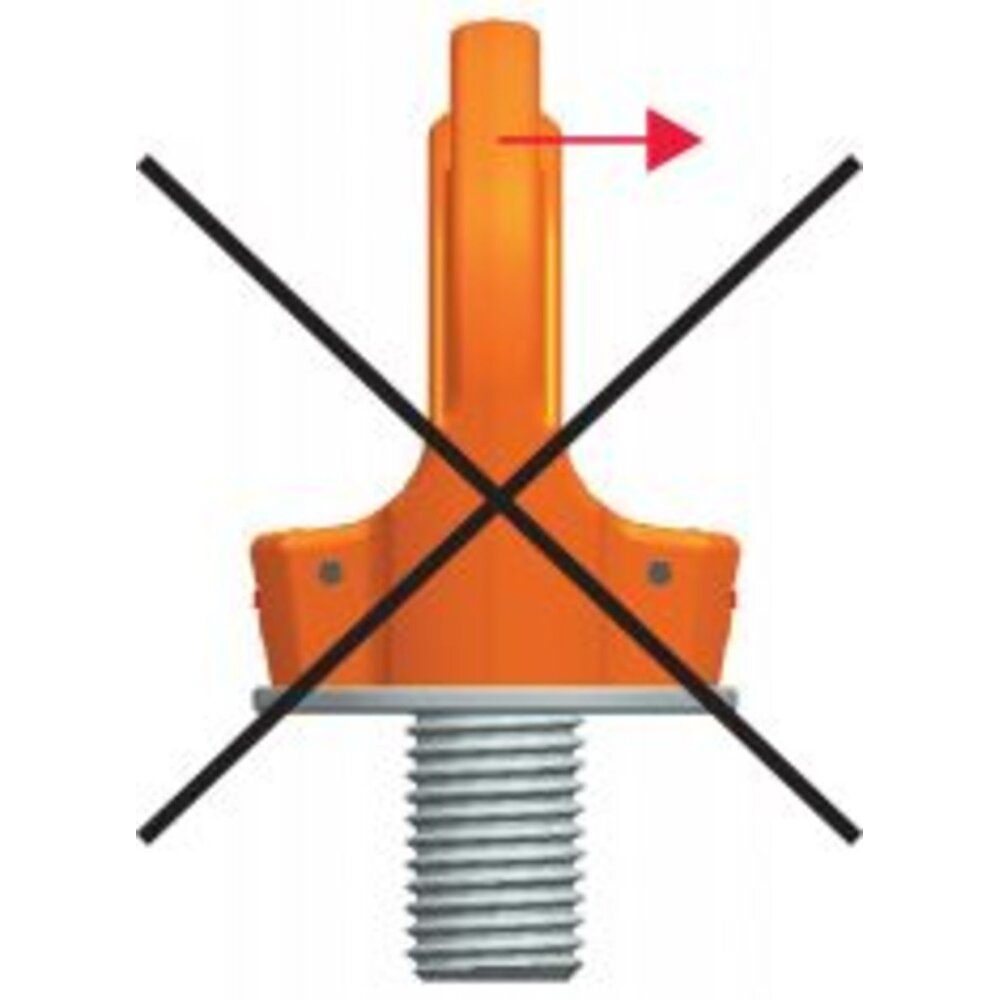

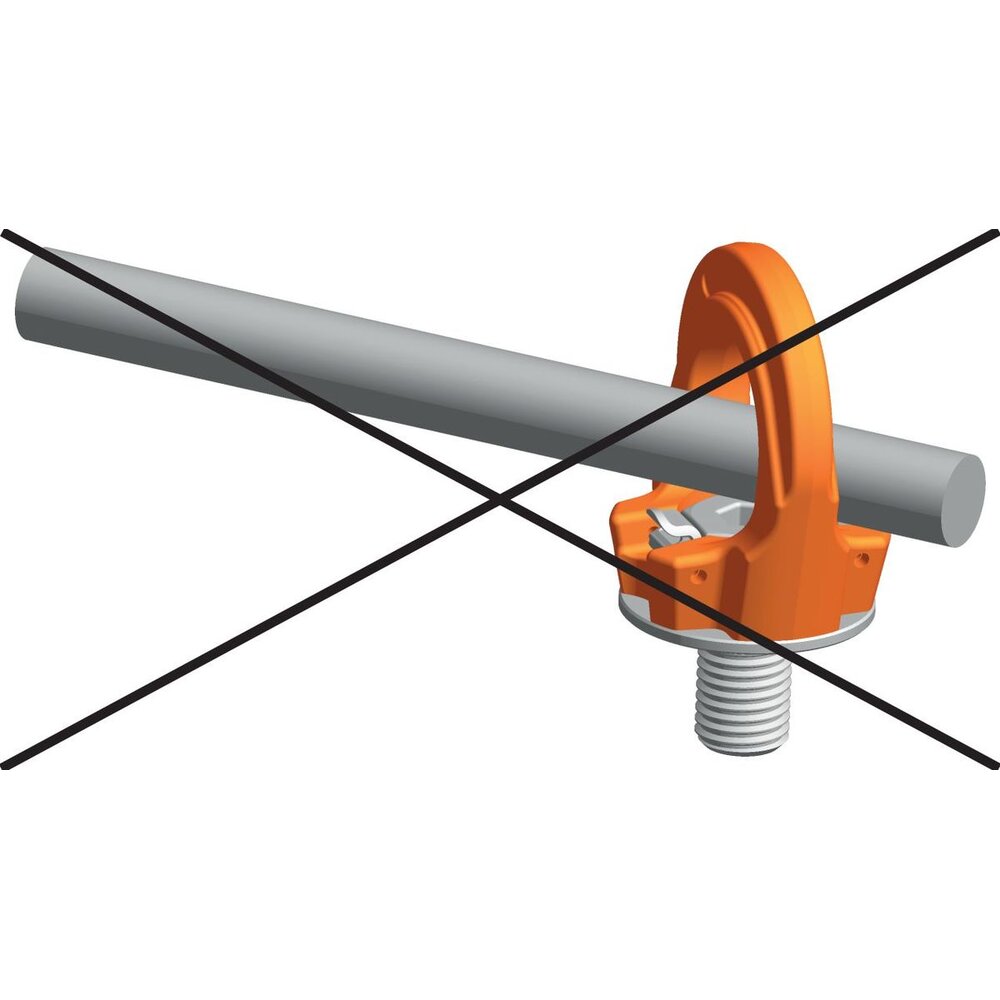

Non permissible usage

Make sure when choosing the assembly that improper loading can not arise e.g. if:

- The direction of pull is obstructed

- Direction of pull is not in the foreseen area (see picture 4)

- Loading ring rests against edges or loads

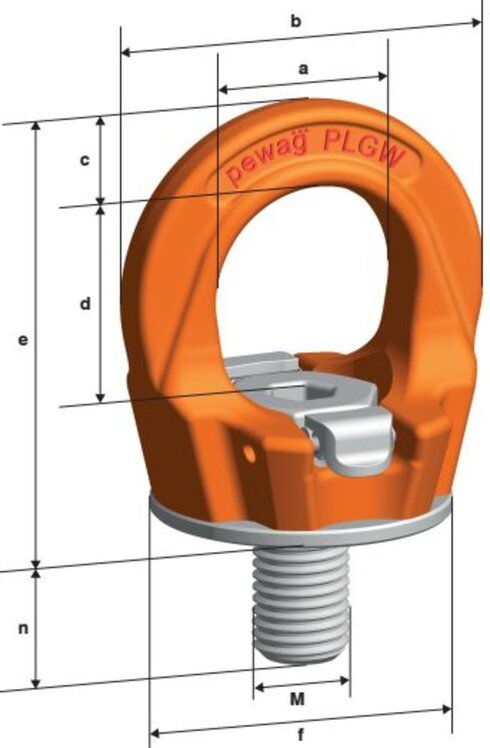

To calculate the necessary thread length (L):

L= H + S + K + X

H = Material height

S = Thickness of the washer

K = Height of the nut (depending on the thread size of the screw)

X = Excess length of the screw (twofold pitch of the screw)

L max. = n max.

In case of requesting a lifting point with a special thread length, please mention the requested thread length “L”.

pewag provides, along with the standard and maximum thread lengths, specially customised thread lengths.

Supplied customised and maxium thread lengths include a washer and a crack-tested, corrosion-proofed screw nut.

- Material: Alloy steel.

- Marking: According to standard, CE-marked, WLL, thread size and ID number.

-

Standard:

EN 1677-1

except grade/WLL

- Safety factor: 4:1