Wire rope DSC8

Product information

Typical applications: When a high MBL is required for a multipart reeving hoist system: electric hoists, twin hoist systems (right and left ropes), boom hoist and pendant rope for mobile cranes and tower cranes.

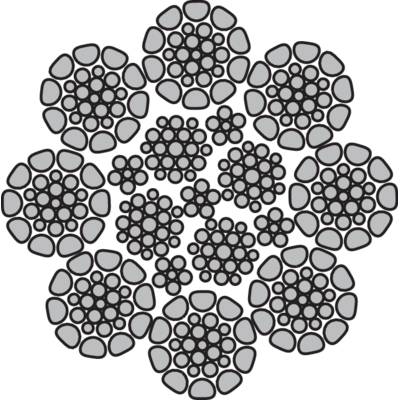

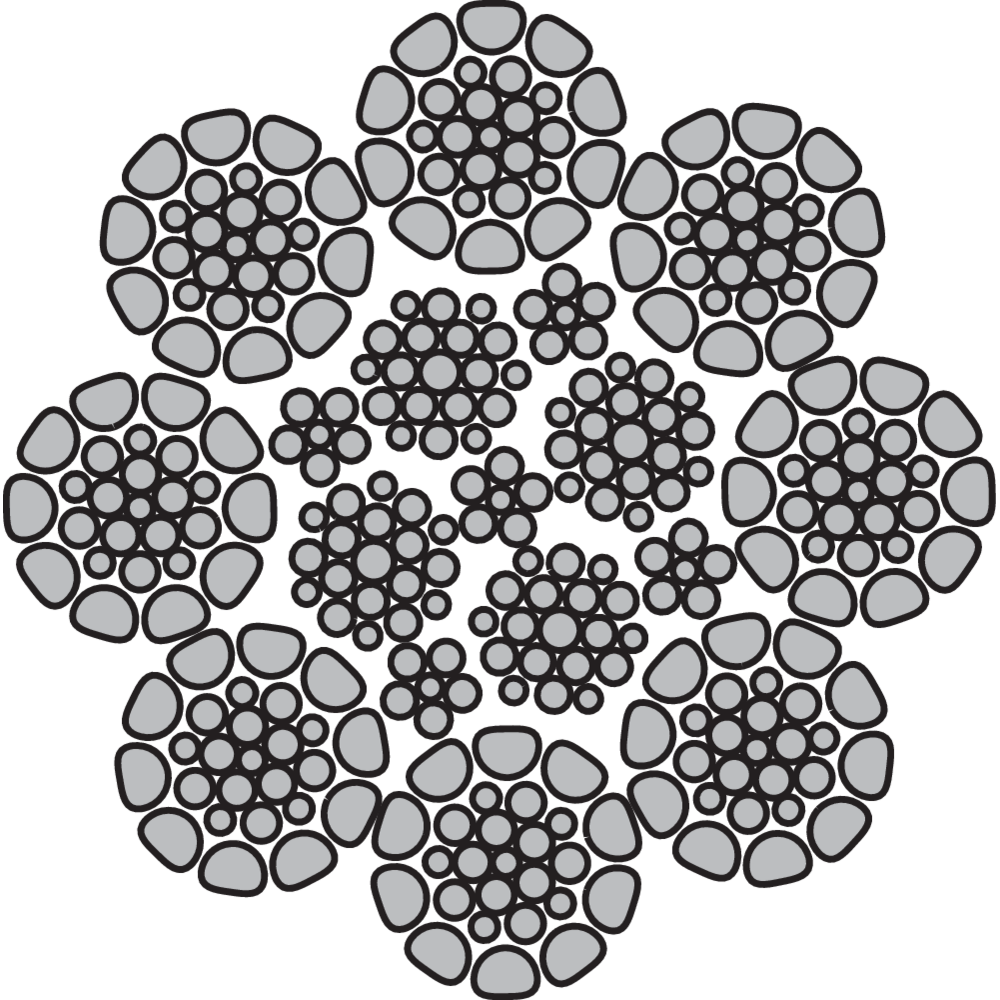

Fill factor: 10 mm - 0,74, 11-32 mm - 0,73, 33-50 mm - 0,71.

Standard: EN 12385-4

ISO 4309 Rope Category No: 10mm RCN.04, 11-22mm RCN.09, 24-50mm RCN.11

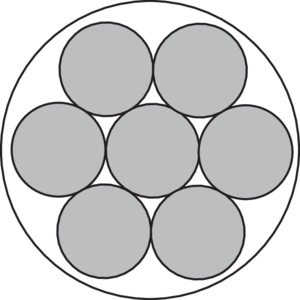

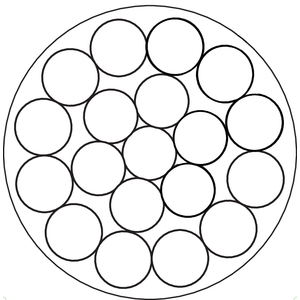

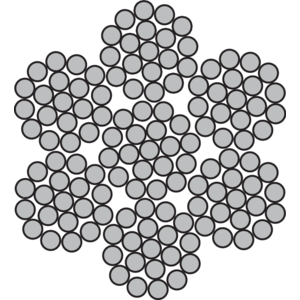

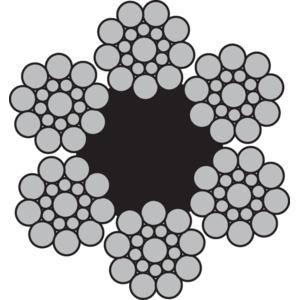

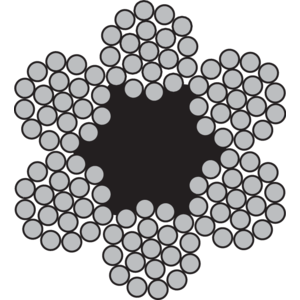

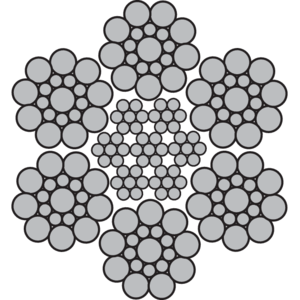

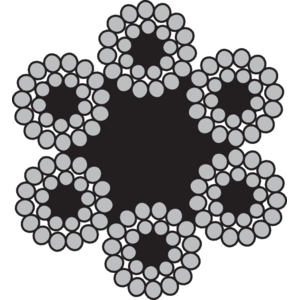

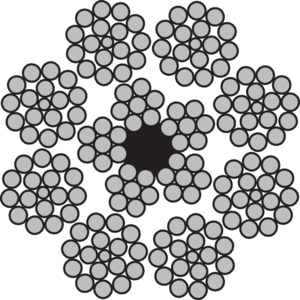

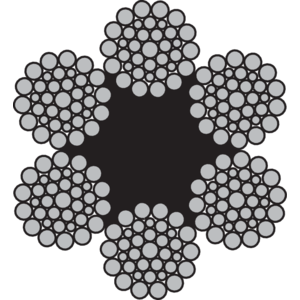

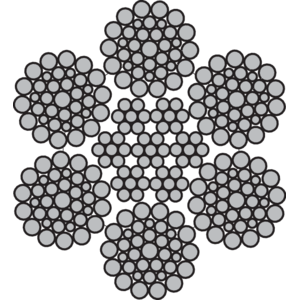

- Rope construction: 8 compacted strands closed in a parallel lay together with the inner core strands.

- Note: Due to its particular full unilay parallel closing (outer/inner strands), this rope is very sensible to the rotation and fleet angle. Cannot be used for big lifting heights, unguided loads a

- RCN: 04

-

Overhead cranes

-

Tower crane

-

Mobile port crane

-

Offshore crane

-

Crawler crane

-

Container crane