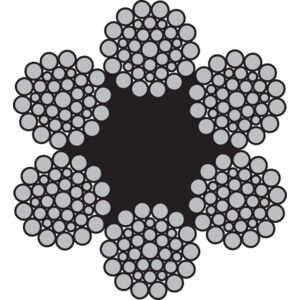

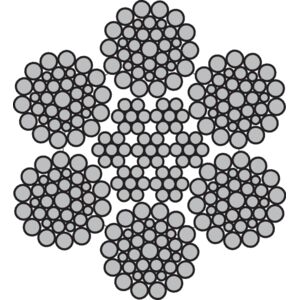

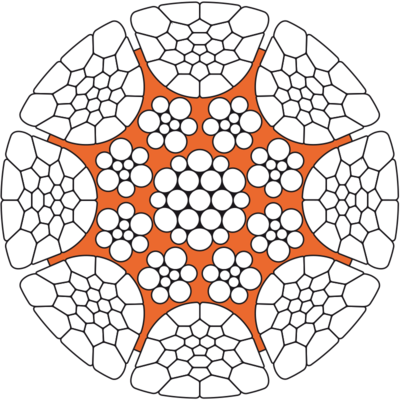

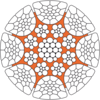

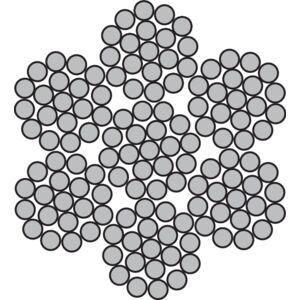

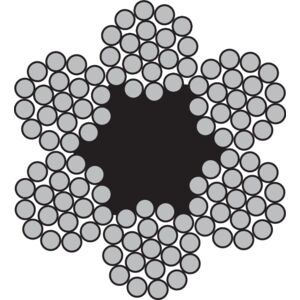

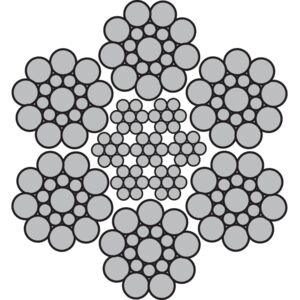

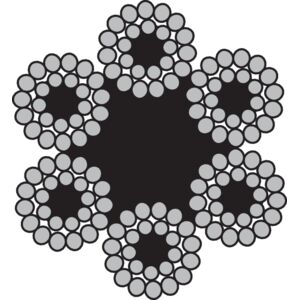

Wire rope construction: veropower 8 is a rotary swaged 8-strand, non-rotation-resistant rope in parallel lay construction with compacted outerstrands and a rope core covered with a plastic layer. It provides the highest breaking strength of all non rotation-resistant wire ropes and offers superior resistance to drum crushing.

Features:

- All strands are compacted and rotary swaged.

- Extremely high breaking strength and is very resistant against abrasion.

- Suitable for multi layer spooling systems with guided loads.

- Fully lubricated

ISO 4309

Rope Category No: Up to 40mm RCN.09, 41-46mm RCN.11, > 46mm RCN.13.

- Marking: According to standard

- Standard: EN 12385-4

- Warning: veropower 8 may not be used with a swivel.

- RCN: 09

- Tolerance Ø: +2% to +4%

Steel wire rope Veropower 8

Steel wire rope Veropower 8

Steel wire rope Veropower 8

Steel wire rope Veropower 8

![6x19-FC Seal[new]_225mm](/pim/assortment/Steel%20wire%20ropes/General%20rope/1743/image-thumb__1743__product-small/6x19S-FC.94b45451.jpg)

![8x17-IWRC[new]_225mm](/pim/assortment/Steel%20wire%20ropes/Other%20Crane%20Rope/1537/image-thumb__1537__product-small/8x17-iwrc-new-_225mm.eeba048f.jpg)