Use in Adverse Environments

Temperature affect on working load limit (WLL)

Account should be taken of the maximum temperature that can be reached by the wire rope sling in service. This is difficult in practice but underestimation of the temperature should be avoided.

The table below summarises the necessary de-rated working load limits of a sling due to temperature, taking into account the type of rope termination, the ferrule material and the core of the rope.

When wire rope slings are to be used in temperatures below -40 °C CERTEX should be consulted.

The use of wire rope slings within the permissible temperature ranges given in the table does not require any

permanent reduction in working load limit when the rope is returned to ambient temperature.

| Termination type | Ferrule- material |

Rope core |

De-rated working load limit expressed as % of WLL of the sling Temperature Celsius |

|||||

|---|---|---|---|---|---|---|---|---|

| Ferrule | Aluminium | Fibre | 100 | Do not use | Do not use | Do not use | Do not use | Do not use |

| Ferrule | Aluminium | Steel | 100 | 100 | Do not use | Do not use | Do not use | Do not use |

| Ferrule | Steel | Fibre | 100 | Do not use | Do not use | Do not use | Do not use | Do not use |

| Ferrule | Steel | Steel | 100 | 100 | 90 | 75 | 65 | Do not use |

| Splice | Fibre | 100 | Do not use | Do not use | Do not use | Do not use | Do not use | |

| Slice | Steel | 100 | 100 | 90 | 75 | 65 | Do not use | |

| Rope pear socket | Zinc | Fibre | -40 - 80ºC | 100 | ||||

| Rope pear socket | Zinc | Steel | -40 - 120ºC | 100 | ||||

| Rope pear socket | 2-component | Fibre | -50 - 80ºC | 100 | ||||

| Rope pear socket | 2-component | Steel | -50 - 80ºC | 100 | ||||

Acidic conditions

Wire rope slings should not be used either immersed in acidic solutions or exposed to acid fumes.

Chemical affect

CERTEX should be consulted in case the slings are to be exposed to chemicals combined with high temperature.

Safe Use

Preparation

Before starting the lift, it should be ensured that the load is free to move and is not bolted down or otherwise obstructed.

Packing may be required where a rope comes into contact with a load in order to protect either the rope or the load or both, since sharp corners of hard material may bend or damage the rope or, conversely, the rope may damage the load because of high contact pressure. Corner protection should be used to prevent such damage.

In order to prevent dangerous swaying of the load and to position it for loading, a tag line is recommended.

When loads are accelerated or decelerated suddenly, dynamic forces occur which increase the stresses in the rope. Such situations, which should be avoided, arise from snatch or shock loading e.g. from not taking up the slack rope before starting to lift, or because of the shock from falling load being stopped.

Mass of the load

It is essential that the mass of the load to be lifted is known.

Gravity

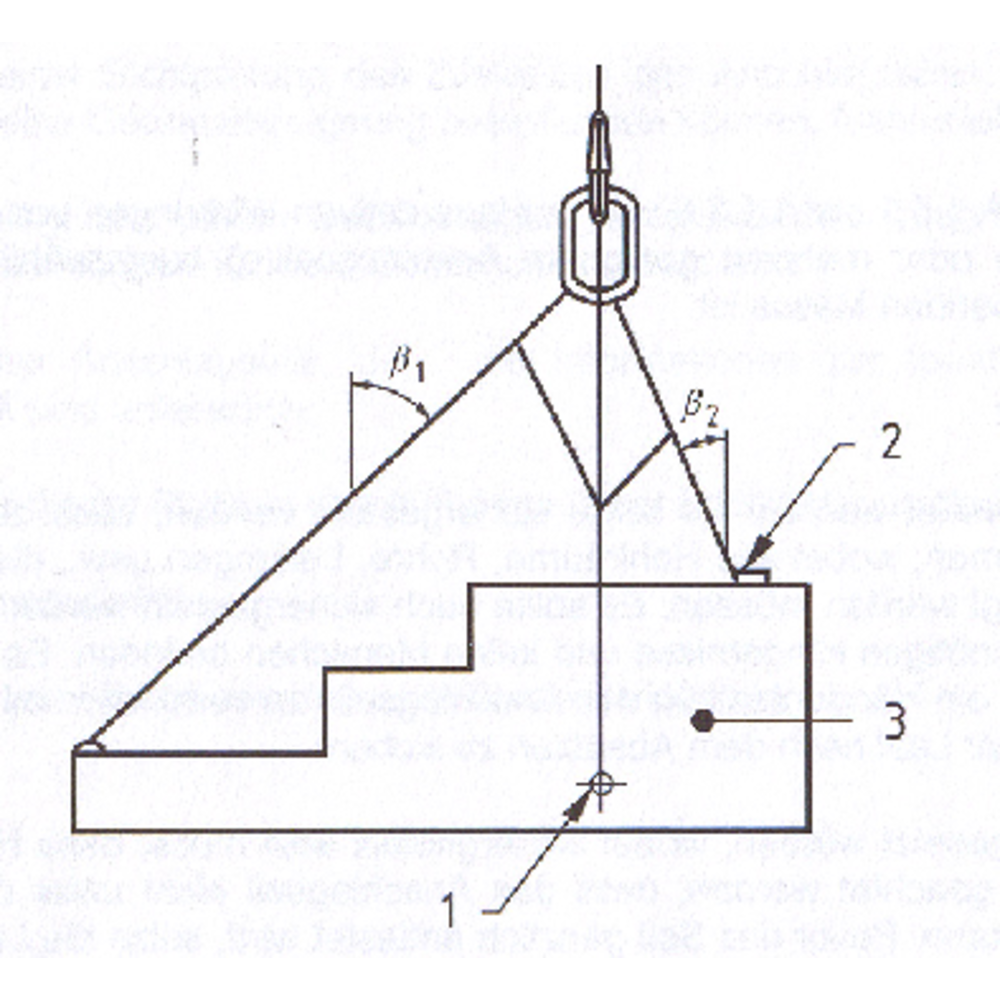

It is assumed that the attachment point of the hook is directly above the centre of gravity of the load. To lift the load the following conditions should be met:

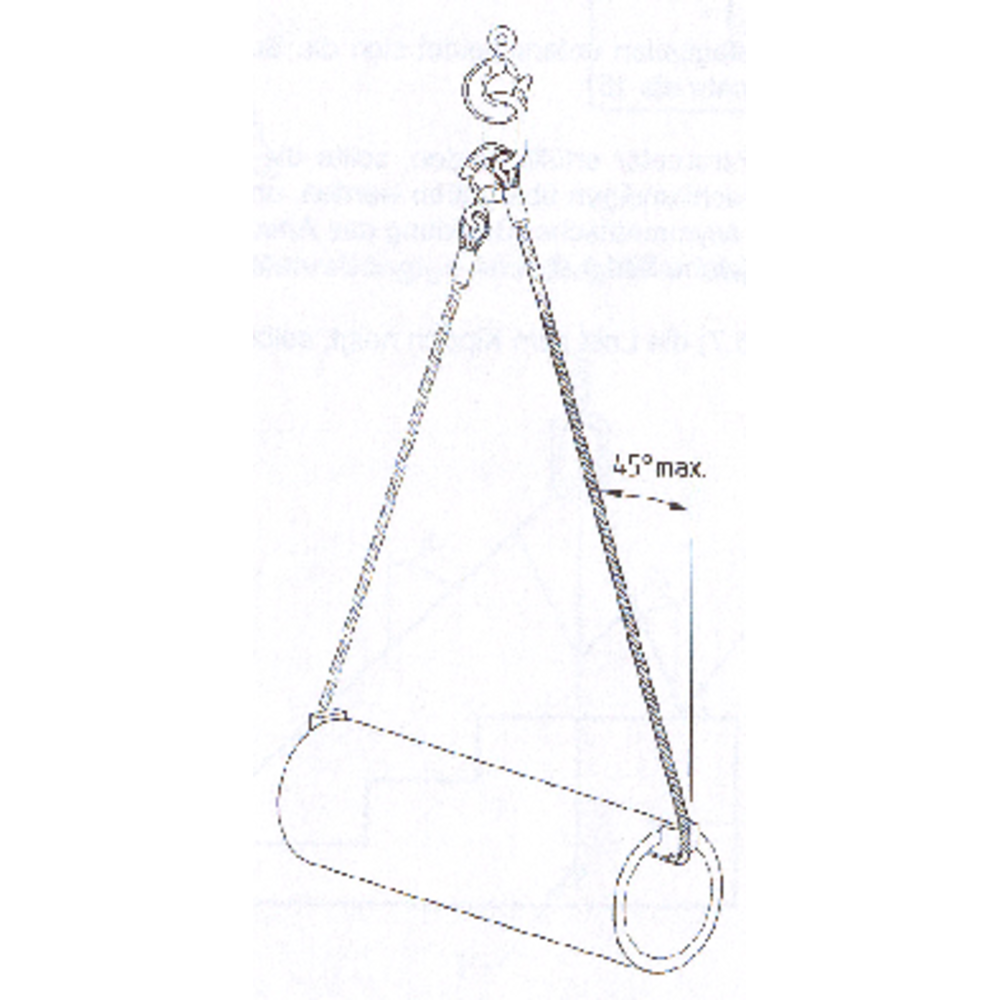

a) For single-leg and single endless wire rope slings the attachment point should be vertically above the centre of gravity.

b) For 2-leg wire rope slings the attachment points should be either side of and above the centre of gravity.

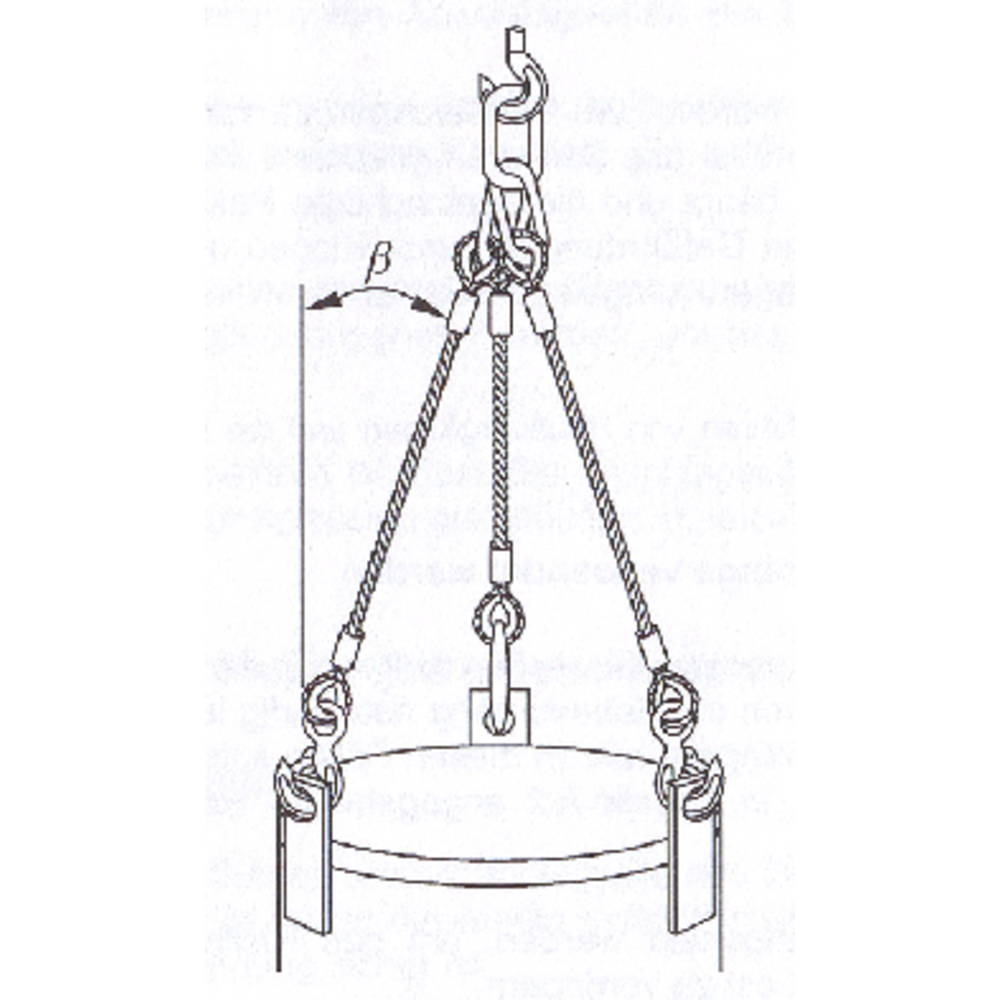

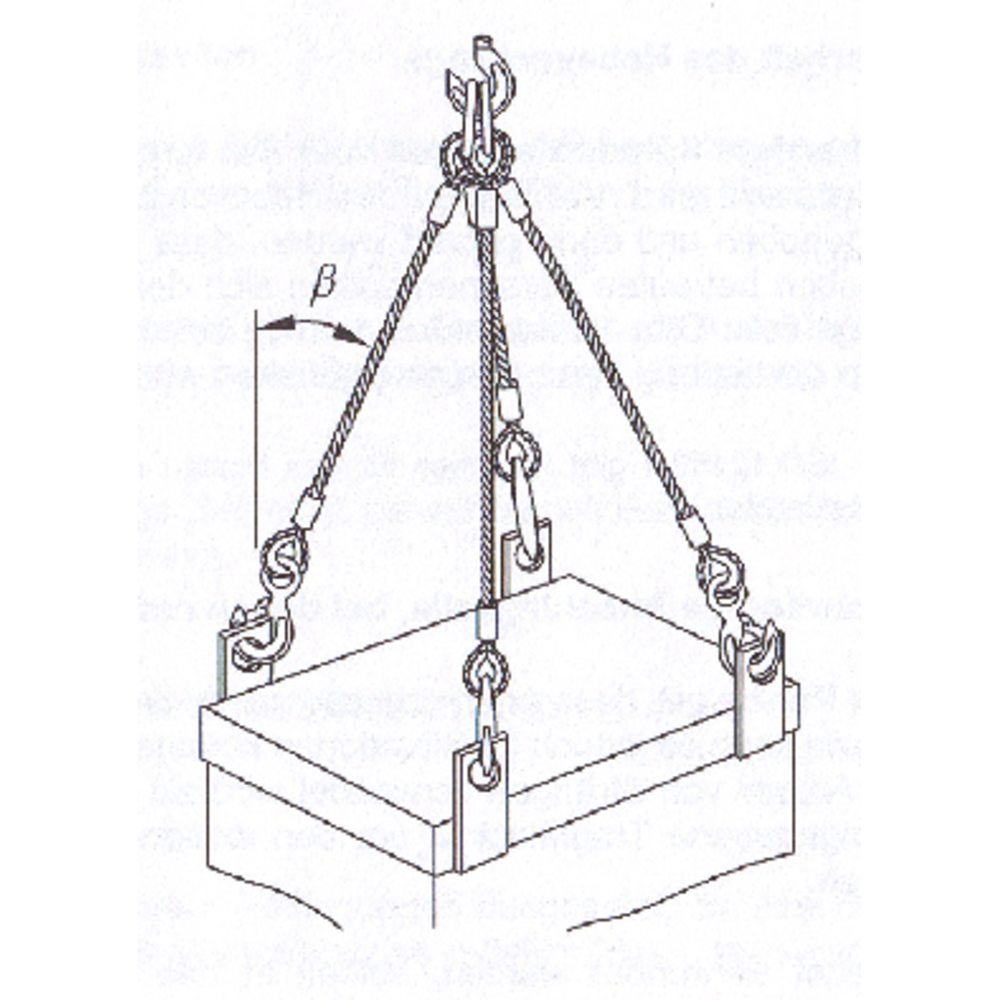

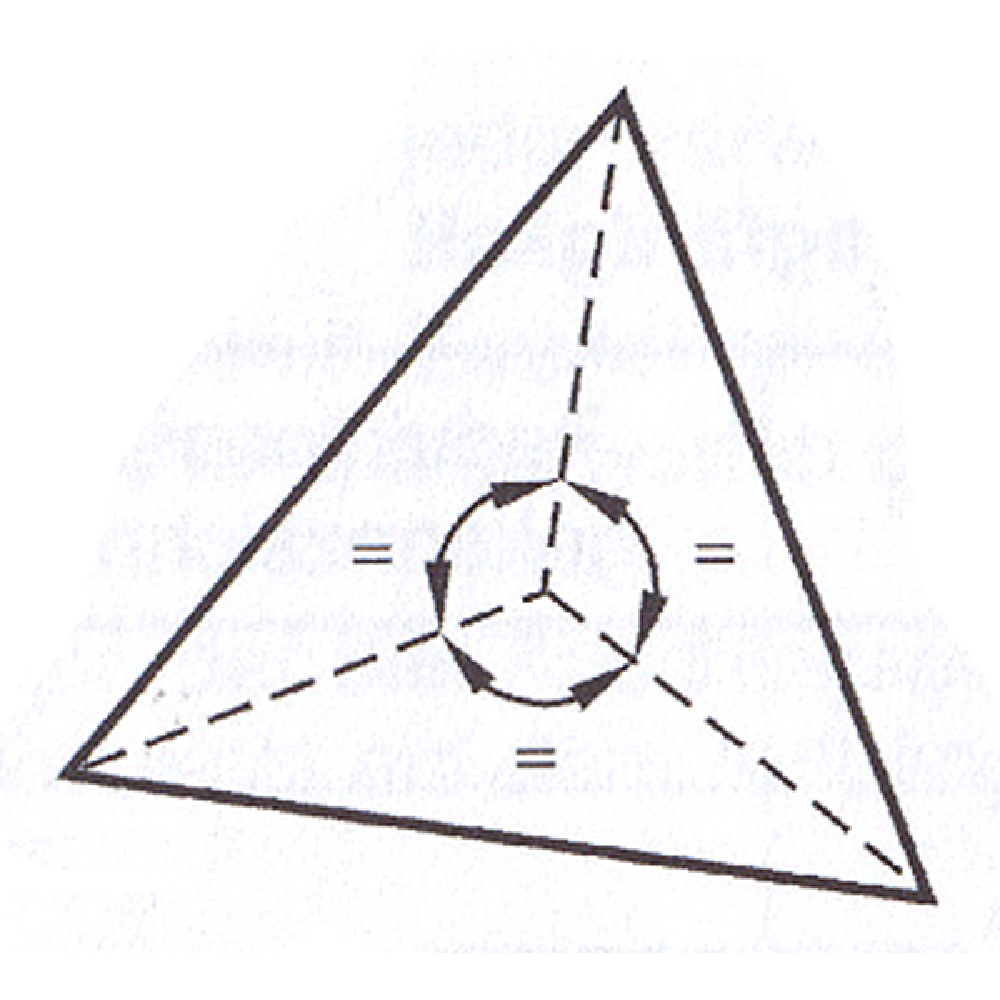

c) for 3- and 4-leg wire rope slings the attachment points should be distributed in plan around the centre of gravity. It is preferable that the distribution should be equal and that the attachment points are above the centre of gravity.

If the attachment points using a) or b) are at or below the centre of gravity, other lifting arrangements should be used.

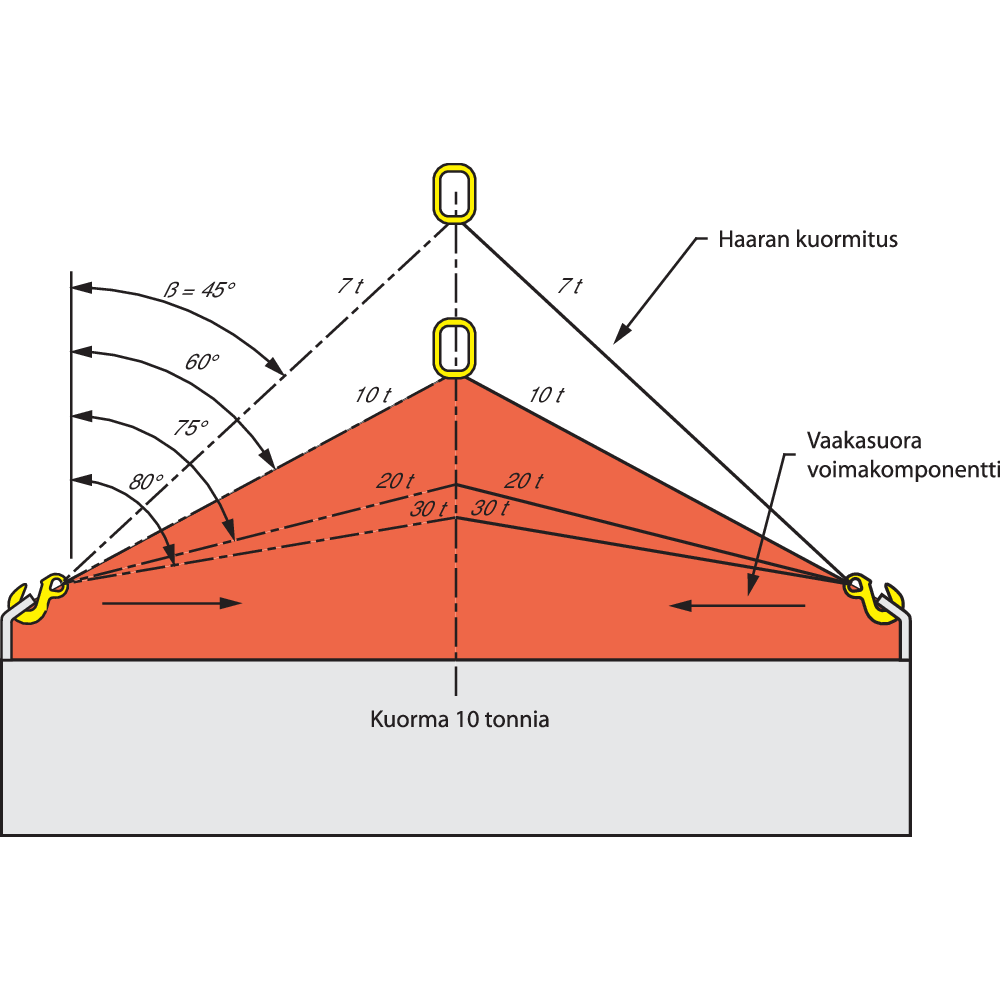

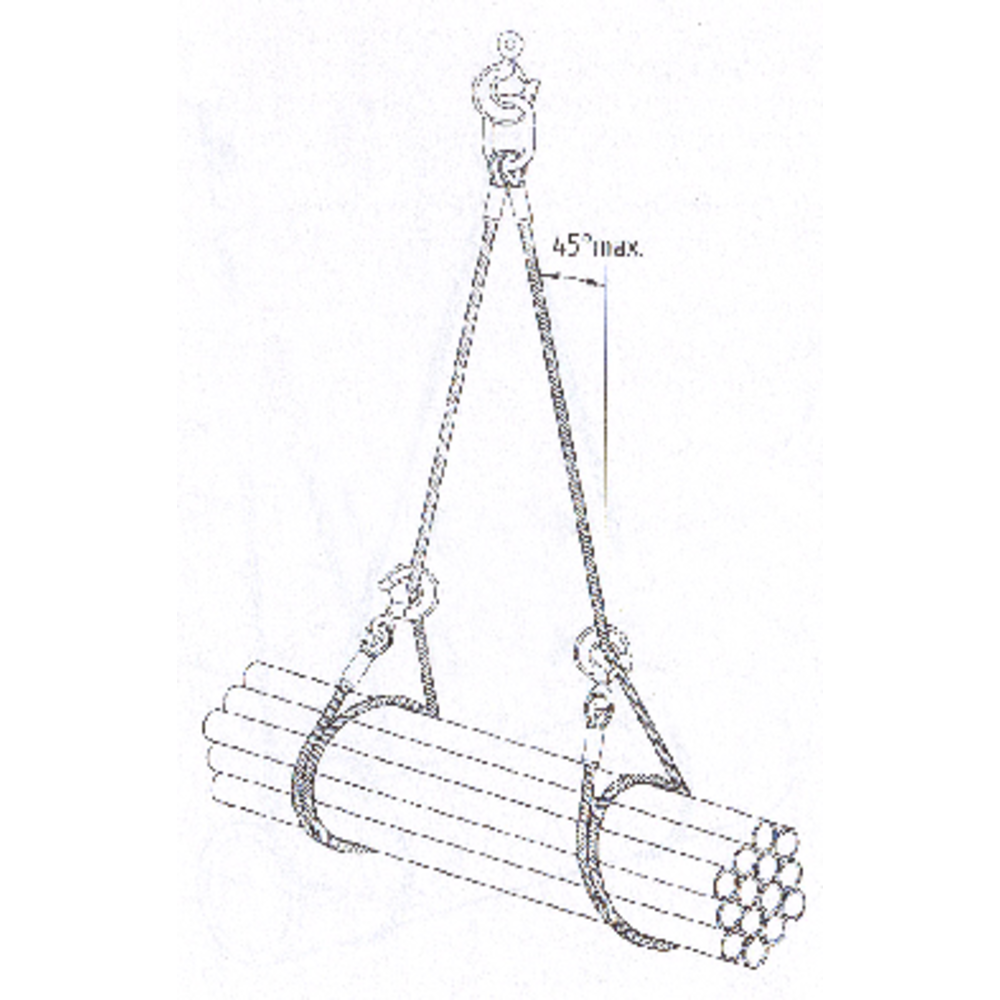

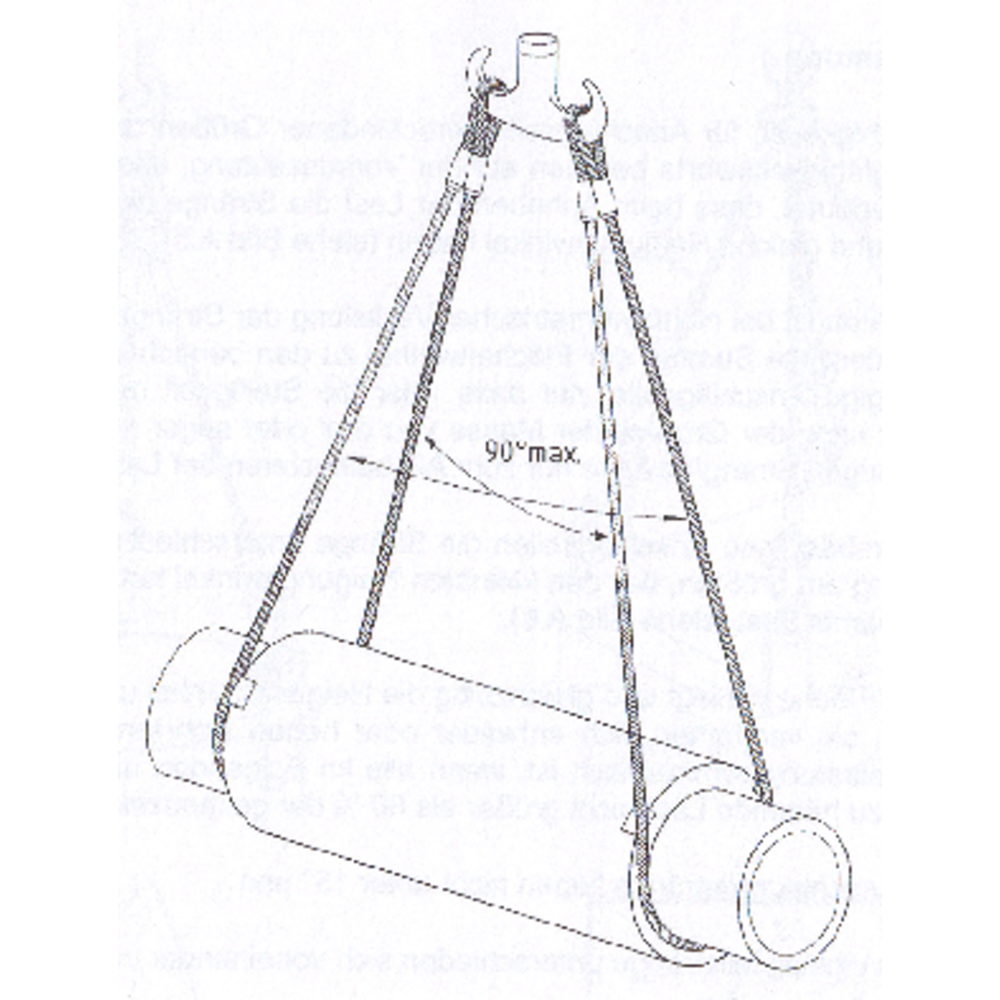

When using 2-, 3- and 4-leg wire rope slings the attachment points and sling configuration should be selected to achieve angles between the sling legs and the vertical within the range marked on the sling. Preferably all angles to the vertical (angle â) should be equal. Angles to the vertical of less than 15° should be avoided if possible as they present a significantly greater risk of load imbalance.

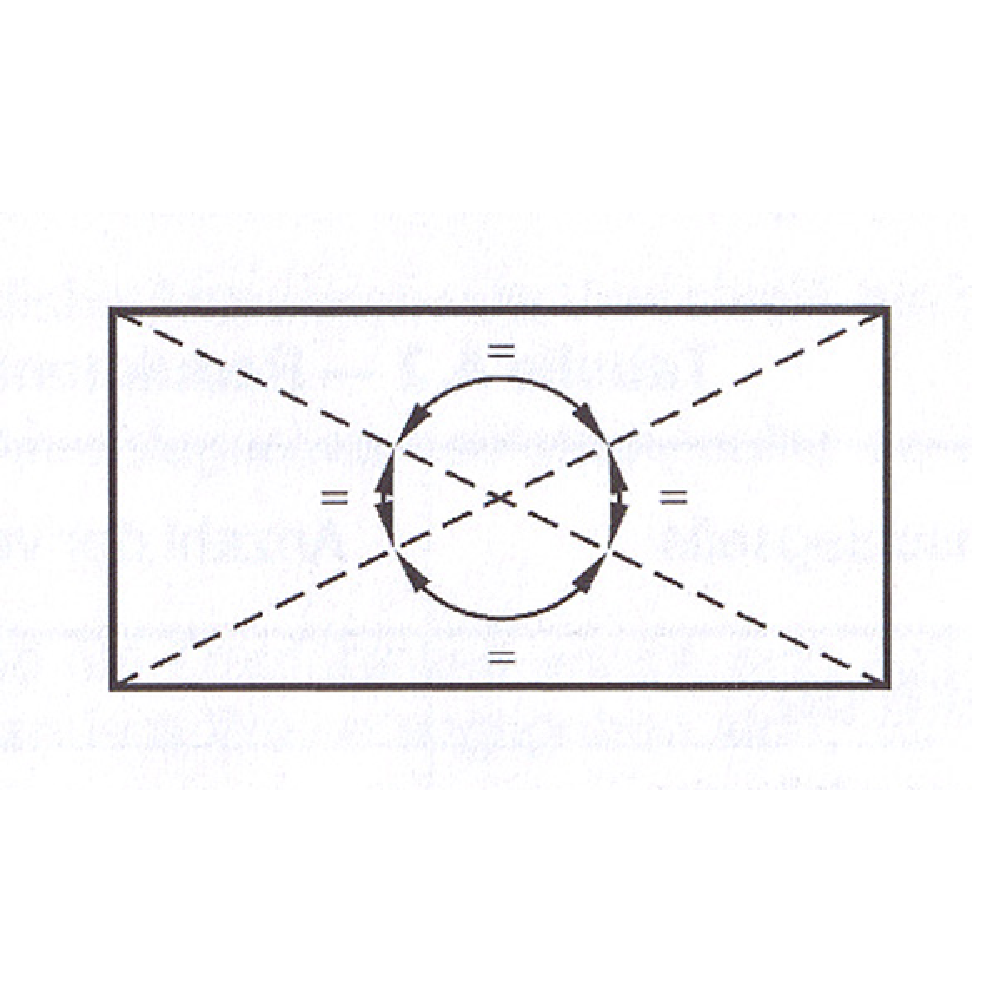

All multi-leg slings exert a horizontal component of force (see figure) which increases as the angle between the sling legs is increased. Care should always be taken to ensure that the load to be moved is able to resist the horizontal component of force, without being damaged.

Method of connection

A wire rope sling is usually attached to the load and the lifting machine by means of terminal fittings. Sling legs should not be twisted or knotted.

The lifting point should be seated well down in a hook, never on the point or wedged in the opening. The sling hook should be free to incline in any direction so as to avoid bending. For the same reason, the terminal fitting should be free to incline in any direction on the hook to which it is fitted.

The rope may be passed under or through the load to form a choke hitch or basket hitch. When using basket hitch method and where it is necessary, due to the danger of the load tilting, to use more than one sling, this should preferably be done in conjunction with a lifting beam.

When a wire rope sling is used in a choke hitch, the rope should be allowed to assume its natural angle and should not be hammered down.

When attaching the sling to the lifting hook, ensure that there is adequate clearance to permit articulation and to prevent damage to the sling. Never force, hammer or wedge a sling into position. If there is insufficient clearance, fit a shackle between the sling and the hook.

To prevent the formation of kinks and subsequent weakening of the rope of slings having soft eye terminations, ensure that the effective diameter of the shackle pin / hook is at least twice the diameter of the rope.

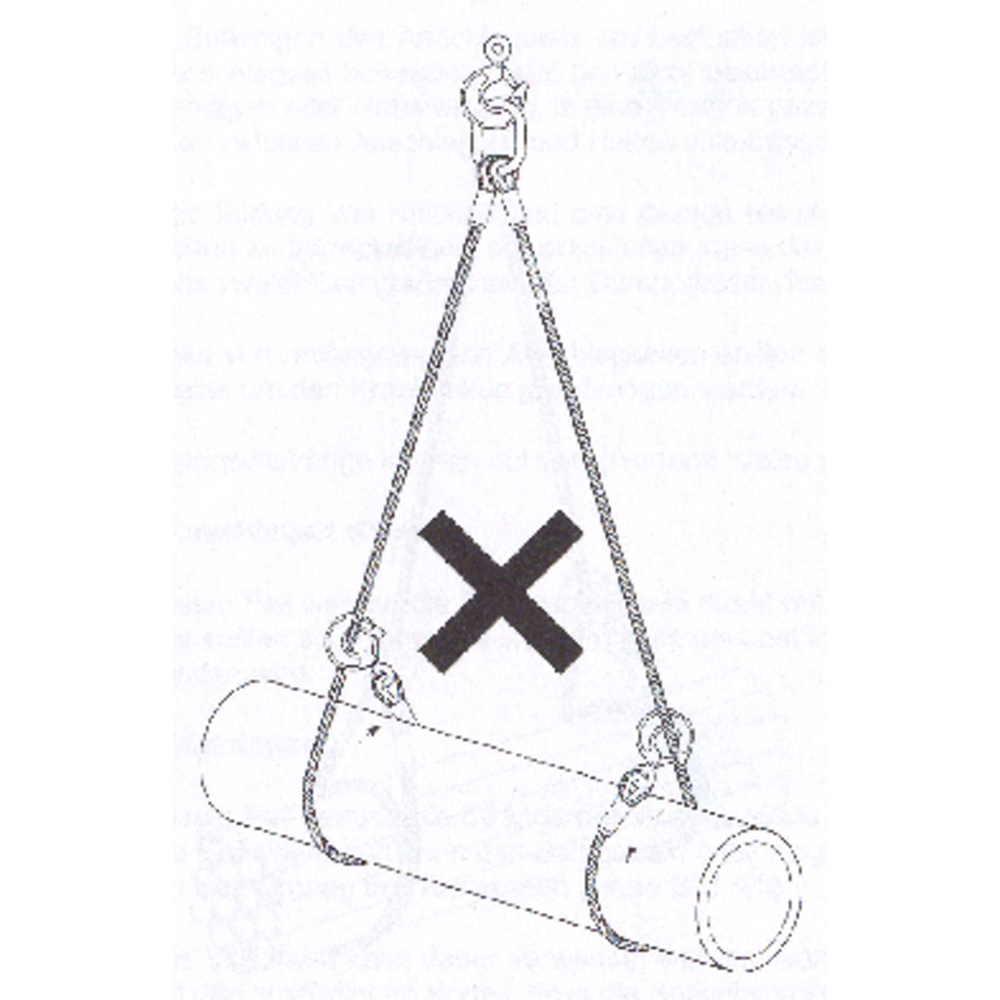

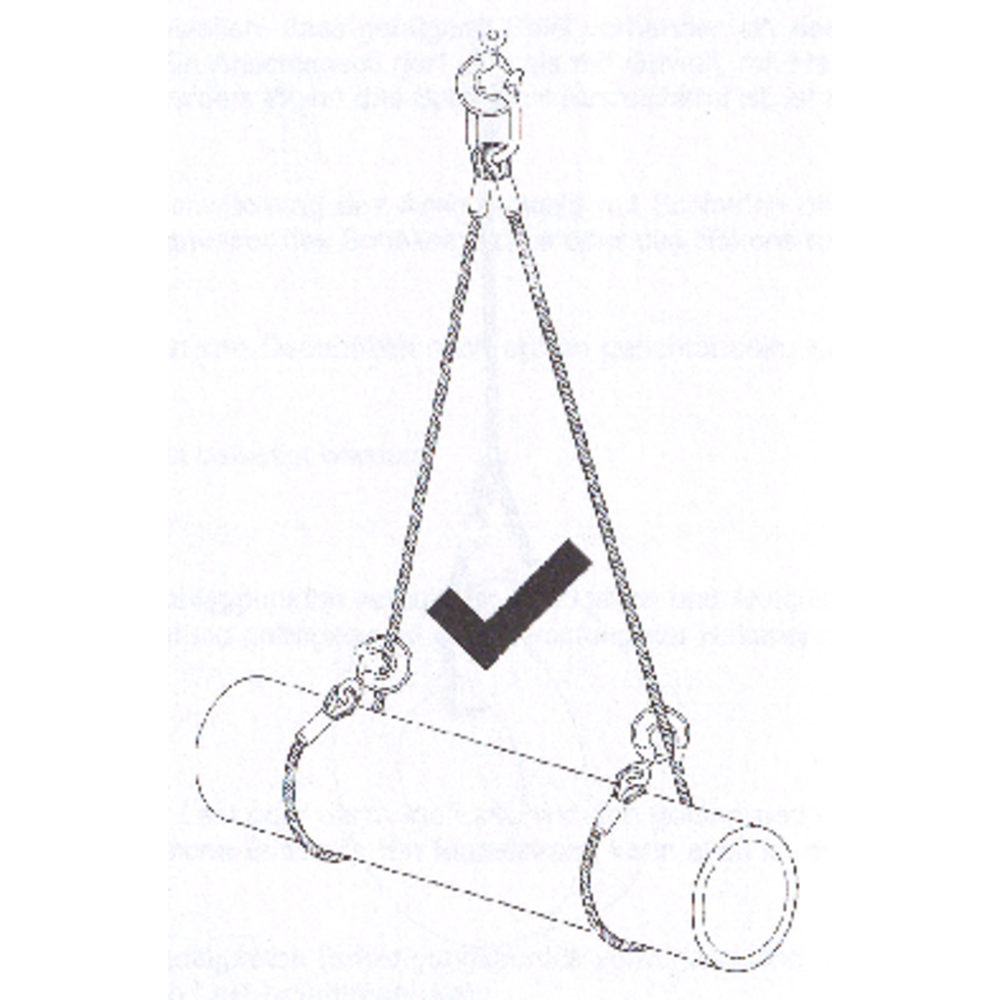

In the case of a mutli-leg sling the tip of a sling hook should be directed outwards. No rope should be wrapped around a crane hook.

The steel wire rope sling may be attached to the load in several ways:

Straight leg

In this case lower terminals are connected to the attachment points. Selection of hooks and attachment points should be such that the load is carried in the seat of the hook and tip loading of the hook is avoided.

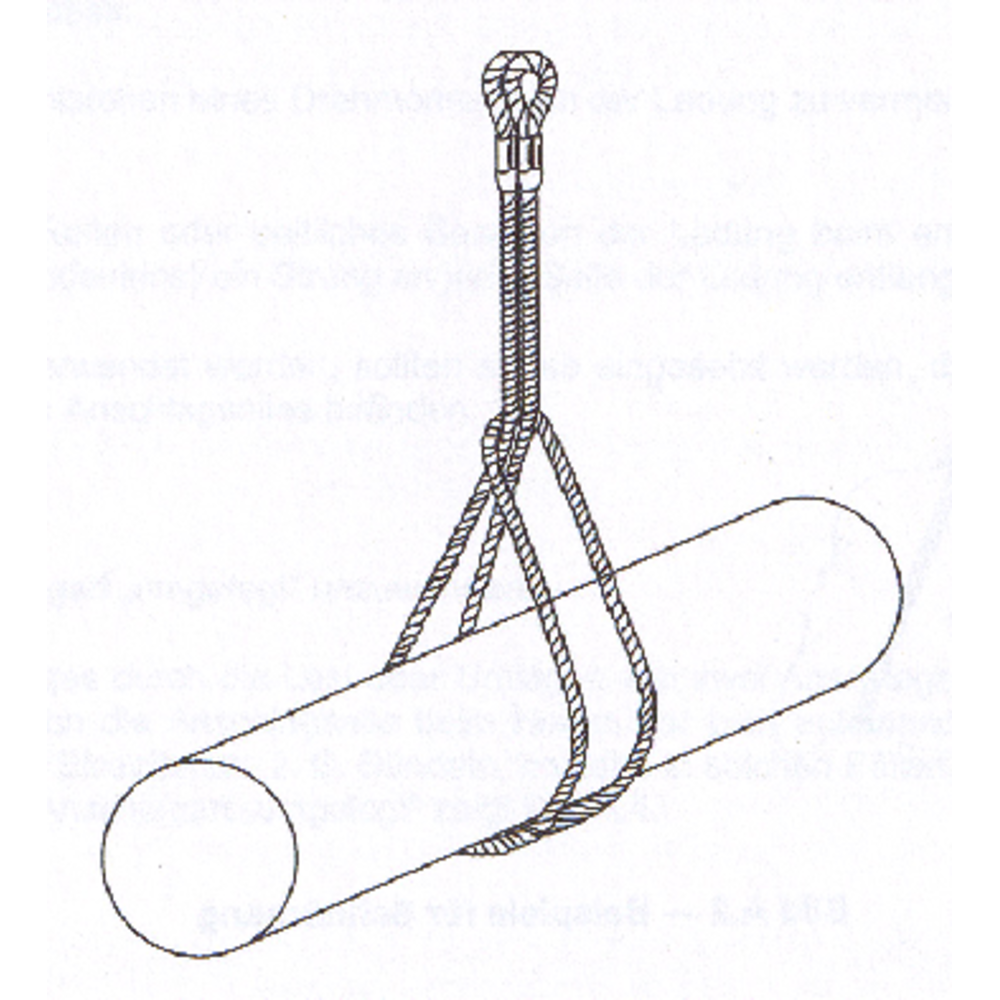

Choke hitch

In this case sling legs are passed through or under the load and the lower terminal back hooked are reeved onto the rope. This method can, therefore, be used where no suitable attachment points are available and has the additional advantage that the wire rope sling legs tend to bind the load together.

Where choke hitch is employed the working load limit (WLL) of the sling should be no more than 80 % of that marked.

If two or more wire rope sling legs are used in a choke hitch or a double choke hitch care should be taken:

1) if it is important, to avoid imparting a torque to the load, to align the chokes;

2) if it is important, to avoid the load rolling or moving laterally when first lifted, to ensure that (at least) one leg passes either side of the load.

When endless slings are used they should be so placed such that any joining ferrules or splices are in the free length of the sling.

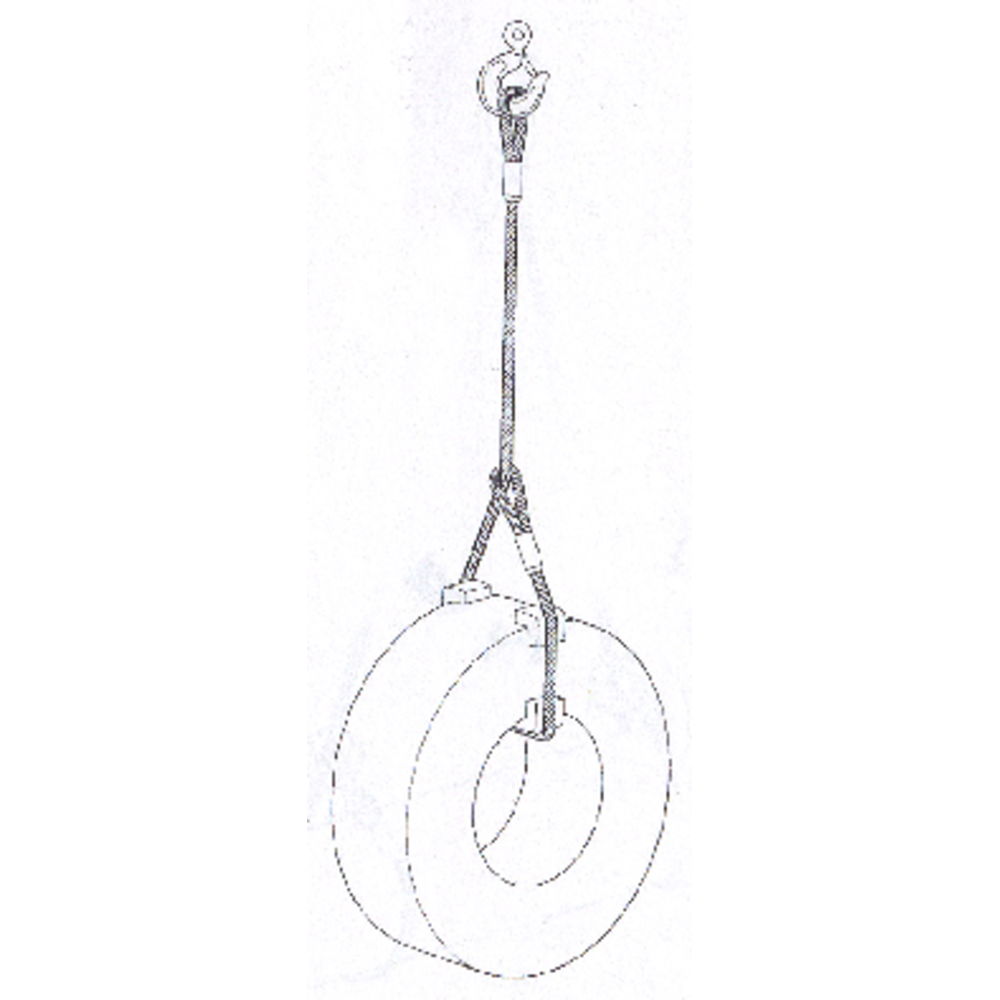

Basket hitch

There are two methods of forming a basket hitch; passing a single sling through a load or wrapping two slings around the load. The second method is not suitable where the slings are able to move towards each other when the load is lifted or when lifting loads which are not held together such as loose bundles; a choke hitch is preferred.

Symmetry of loading

Working load limits are given for wire rope slings in a range of sizes and for different configurations. These WLL values have been determined on the basis that the loading of the wire rope sling is symmetrical. This means that when the load is lifted the wire rope sling legs are symmetrically arranged in plan and subtend the same angles to the vertical.

In the case of 3-leg wire rope slings, if the legs are not symmetrically arranged in plan the greatest tension will be in the leg where the sum of the plan angles to the adjacent legs is greatest. The same effect will occur in 4-leg wire rope slings except that the rigidity of the load should also be taken into account. With a rigid load the majority of the mass must be assumed to be taken by only 3- or even 2-legs with the remaining leg or legs serving only to balance the load.

In the case of 2-, 3- and 4-leg wire rope slings, if the legs subtend different angles to the vertical the greatest tension will be in the leg with the smallest angle to the vertical. In the extreme case, if one leg is vertical, it will carry all the load.

If there is a lack of symmetry in plan and unequal angles to the vertical, the two effects will combine and may either be cumulative or tend to negate each other; but if the following is satisfied, the loading can be assumed to be symmetric providing the load to be lifted does not exceed 80% of marked WLL:

a) wire rope sling leg angles to the vertical are all not less than 15°; and

b) wire rope sling leg angles to the vertical are all within 15° to each other; and

c) in the case of 3- and 4-leg wire rope slings, the sum of the plan angles to the adjacent legs is within15° of each other.

If not all of the above parameters are satisfied then the loading should be considered as asymmetric and the lift referred to a competent person to establish the safe working load for the wire rope sling. Alternatively, in the case of asymmetric loading, the wire rope sling should be rated at half the marked WLL.

If during a test lift the load is unstable it should be lowered and the slinging arrangement changed. This can be done by moving the attachment points or by using suitable shortening device in one ore more parts. Those shortening device shall be used according to CERTEX recommendations.

Safety of lift

Hands and other parts of the body should be kept away from the sling to prevent injury as the slack is taken up. When ready to lift, the slack should be taken up until the rope is taut. The load should be raised slightly and a check made that it is secure and assumes the position intended. Persons undertaking the lift should be aware of the potential hazards associated with the load tilting or swaying. This is especially important with basket or other loose hitches where friction retains the load.

Multi-leg wire rope slings with less than the full number of legs in use

As a general principle, wire rope slings should be used only for the purpose for which they have been designed. In practice, however, occasions may arise when a lift needs to be made using a smaller number of legs than the number of legs in the sling. In such cases the WLL should be reduced from that marked on the sling by applying the relevant factor given in table below.

Legs that are not in use should be hooked back to reduce the risk of such legs swinging freely, or snagging when the load is moved.

WLL-factors

| Types of sling | Number of legs used | Factor to apply to marked WLL |

|---|---|---|

| 2-leg | 1 | 1/2 |

| 3- and 4-leg | 2 | 2/3 |

| 3- and 4-leg | 1 | 1/3 |

Working Load Limit (WLL)

Taking into consideration the recommendations and the cumulative effects of de-rating, the method of slinging should be decided and a suitable wire rope sling or wire rope slings selected so that the mass to be lifted does not exceed the WLL.

Landing the load

The landing site should be prepared. It should be ensured that the ground or floor is of adequate strength to take the load taking account of any voids, ducts, pipes etc. which may be damaged or collapse. It should also be ensured that there is adequate access to the site and that it is clear of any unnecessary obstacles and people. It is preferable to use timber bearers or similar material to avoid trapping the sling or to protect the floor or load or to ensure the stability of the load when landed.

The load should be landed carefully ensuring that hands and feet are kept clear. Care should be taken to avoid trapping the wire rope sling beneath the load as this may damage it. Before allowing the rope to become slack, the load should be checked to ensure that it is properly supported and stable. This is especially important when several loose objects are in basket hitch and choke hitch.

When the load is safely landed the wire rope sling should be carefully removed to avoid damage or snagging or cause the load to topple over. The load should not be rolled off the sling as this may damage the sling.

Storage of wire rope slings

When not in use wire rope slings should normally be kept on a properly designed rack. They should not be left lying on the ground where they may be damaged.

If the wire rope slings are to be left suspended from a crane hook, the sling hooks should be engaged in an upper link to reduce the risk of sling legs swinging freely or snagging.

If it is likely that wire rope slings will be out of use for some time they should be cleaned, dried and protected from corrosion, e.g. lightly oiled.

Maintenance

Components that are cracked, visibly distorted or twisted, severely corroded or have deposits that cannot be removed should be discarded and replaced.

Minor damage such as nicks and gouges to terminal fittings may be removed by careful grinding or filing. The surface should blend smoothly into adjacent material without abrupt change of section. The complete removal of the damage should not reduce the thickness of the section at that point to less than the manufacturer’s specified minimum dimensions or by more than 10% of nominal thickness of the section.

Thorough Examination and Discard Criteria

General

An thorough examination is a visual check, performed by an expert and, when required, complemented with other methods, e.g. measurement and/or tests with intent to identify any damage or deterioration that might affect the slings fitness for use.

A thorough examination should be carried out at intervals not exceeding twelve months. This interval should be less where deemed necessary in the light of service conditions.

To facilitate examination, slings may need to be cleaned so as to be free from oil, dirt and rust prior to examination. This can usually be accomplished by using a wire brush. Other methods may be used providing that the parent metal is not damaged. Methods to avoid are those using acids, overheating or removal of metal.

Records of such examinations should be maintained.

The sling should be withdrawn from service if any of the following conditions are present, reached or exceeded:

Sling markings

The sling markings, i.e. information on the sling identification and /or the working load limit, are illegible.

Damaged upper and lower terminals

Wear, distortion or cracking of the upper or lower terminals.

NOTE Particular attention should be paid to signs of opening up, distortion or cracking of the hook, distortion and wear of links or the closing of the thimble, indications that the sling may have been overloaded.

Damaged rope terminations

Wear, distortion or cracking of ferrules or the pulling out of a splice.

Broken wires

Broken wires are detrimental because of

a) the possibility of injury to the user’s hands;

b) the loss of strength in the rope.

Broken wires are usually caused by mechanical damage, although corrosion may also be a factor.

The appearance of well distributed broken wires may have no marked effect on the strength of the sling but the discard criteria in below should be adopted for randomly distributed broken wires and concentrated broken wires respectively.

NOTE To prevent injury to the user’s hands, protruding broken wires can be broken off in the valleys between the strands by reverse bending the wire, with the help of pliers, until fracture occurs. Such actions should be recorded.

Randomly distributed broken wires

6 randomly distributed broken outer wires in a length of 6 d but no more than 14 randomly distributed broken wires in a length of 30d where d is the nominal rope diameter.

Concentrated broken wires

3 adjacent broken outer wires in one strand.

Rope distortion

Kinking, crushing, birdcaging or core protrusion or other damage which distorts the rope structure.

NOTE: The main thing to look for is wires or strands that are pushed out of their original positions in the rope. Slight bends in a rope where wires or strands are still relatively in their original positions would not be considered serious damage.

Rope wear

10% of the nominal rope diameter (d).

Corrosion

Pitting of the wires or loss of flexibility of the rope due to severe internal corrosion.

NOTE Corrosion may occur where slings have been improperly stored or have been used in particularly corrosive conditions, such as moving loads in and out of acid/alkali baths. The effect is readily identified through the loss of flexibility and roughness to the touch. While light surface rusting is unlikely to affect the rope strength, it may be indicative of internal corrosion, the effect of which is not predictable.

Heat damage

Heat damage as evidenced by discolouration of the wires, loss of lubrication or pitting of the wires caused by electric arcing.

Inspection

An inspection is a visual check on the condition of the sling to identify any obvious damage or deterioration that might affect its fitness for use.

The sling should be withdrawn from service and referred to a competent person for thorough examination if any of the following is observed before each use:

a) illegible sling markings, i.e. sling identification and/or working load limit.

b) wear, distortion and/or cracking of the upper or lower terminals and/or ferrules.

c) concentration(s) of broken wires.

d) severe rope distortion, such as kinks or protrusion of the core.

e) significant rope wear.

f) corrosion.

g) heat damage.

General

During service, wire rope slings are subjected to conditions that affect their safety. It is necessary, therefore, to ensure, as far as is reasonably practicable, that the sling is safe for continued use.

The sling should be inspected for any obvious signs of deterioration before each use.

If, at any time there is reason to doubt the safe condition of the sling, it should be withdrawn from service and subjected to a thorough examination.

If the tag or label identifying the sling and its working load limit becomes detached and the necessary information is not marked on the master link, or by some other means, the sling should be withdrawn from service.

Before First Use

Before first use of the wire rope sling it should be ensured that:

a) the sling is precisely as ordered;

b) the manufacturer’s certificate is to hand;

c) the identification and working load limit marking on the sling correspond to the information on thecertificate;

d) full details of the sling are recorded in a register of slings;

e) the actual use is to be as intended.

Hazardous Conditions

Particularly hazardous conditions including offshore activities, the lifting of persons and lifting of potentially dangerous loads such as molten metals, corrosive materials or fissile materials. In such cases the degree of hazard should be assessed by a competent person and the working load limit adjusted accordingly.